Sustainable timber construction with individualised lighting solution 07. April 2021

BERGMOND®WOOD is of a particularly high quality, fine-grained and is used for construction as well as for furniture production. Roman Gabathuler, architect, initiator, and President of the Board of the BERGMOND®WOOD organization has already planned various residential projects and is passionately committed to sustainable timber construction.

For two projects in the Bünderland (CH), Casa Vitalé in Wangs and Casa Viez in Flims, he has so far - at casanatura and together with RIBAG - developed plans for customized lighting.

«Our credo is the construction of light-flooded, comfortable and healthy living spaces», explains Mr. Gabathuler. "This also includes the conceptual design of the energy source building envelope comfort as well as the selection of building materials that are as sustainable as possible".

In both projects, the entire building was realized with BERGMOND®WOOD, from the structural timber to the façade and the entire interior lining of the building such as window frames, doors, stairs, tables, and various built-in furniture. The client, with the support of Mr. Gabathuler, selected the lighting concept, where possible, also supplemented with BERGMOND®WOOD.

Individualised luminaire materialisation

«Due to the special use of BERGMOND®WOOD in the entire interior area, it was very important for us to find suitable luminaires and to present an appropriate lighting concept», Mr. Gabathuler continues. «If the wooden surface is correctly illuminated, the residents can take full advantage of this comfortable materialization. During the day, we make this possible in our projects with appropriate window areas that can be shaded. During the transition period and at night, we give our buildings a new perception and the viewer a new feeling of space through an appropriate lighting concept».

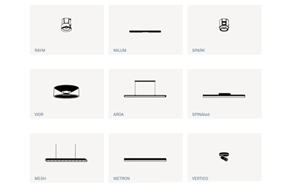

RIBAG manufactured KIVO pendant lamps with BERGMOND®WOOD shades to match the white fir wood used. In addition, all the lights used in the Casa Vitalé were finished with a special paint in pearl mouse grey (RAL7048) according to the customer's wishes, those in the Casa Viez were painted in black, including METRON 80 and CUBO, which are not available in this colour as standard. In addition to KIVO, METRON and CUBO, the product collections AROA, VERTICO, ARVA and VIOR with warm-white light colour were used, the latter also in covered outdoor areas.

Swiss premium product

«RIBAG products manufactured in Switzerland are in line with the idea and implementation of the two projects. Together with the regionally obtained and processed wood, a thoroughly authentic Swiss premium product is created that can be shown», explains Roman Gabathuler. «RIBAG immediately recognized this connection and symbiosis and set the course for individualized production. The fact that RIBAG produces fascias with specially requested wood is unique, just like our BERGMOND®WOOD projects».

«The aim is to naturally reflect the building material mountain moon wood in all its facets and to support its advantages.»

Roman Gabathuler, Architect

For the implementation of the KIVO panels in BERGMOND®WOOD, the client supplied white fir BERGMOND®WOOD to Safenwil. Together with regional wood processing partners, the individual blanks were produced, which Mr. Gabathuler refined with soap. «Since we are planning a building that is as sustainable as possible, sustainable materials are also used. If there is a desire to protect the wood from «yellowing», the wooden surfaces are treated with white floor soap. We do not use lacquer or similar glazes for chemical modification. The aim is to naturally reflect the building material mountain moon wood in all its facets and to support its advantages».

What is BERGMOND®WOOD?

BERGMOND®WOOD grows and flourishes under certain conditions. Decisive factors are the location and the time of felling. These main factors are related to the physical and biological processes in nature that affect the wood.

Mountain

The wood, which is typically fine-grained and evenly grown in the mountain region, is particularly suitable for sustainable and long-term timber constructions. In order to achieve the desired quality, the wood must grow at around 1000 m above sea level in protection forests, on northern slopes and in locations not exposed to wind and with good soil conditions. In principle, BERGMOND®WOOD can be obtained from all tree species, but only species appropriate to the location are used.

Moon

The BERGMOND®WOOD is felled in the period from the end of October to March, in the middle of this seasonally low energy period and ideally during the waning moon phase. As the moon exerts a great influence on the water (e.g. visible at low tide and high tide) and the tree trunk contains a high proportion of water, it is in a so-called homogeneous phase in the phase before new moon. The water withdraws in the sapwood area and the wood changes less after the blow. Felling at the «right time» can refine the properties of the grown wood structure and promote it in a positive sense.

Sustainable timber harvesting

BERGMOND®WOOD grows in Swiss protection forests, in the Sarganserland-Werdenberg-Obertoggenburg region and in the Principality of Liechtenstein, and is sustainably managed. For every tree that is processed into BERGMOND®WOOD, one young person is supported. Protection forests require a careful, differentiated use, which not only focuses on the production of wood, but also on sustainable protection. Large-scale clearings are therefore not possible. The targeted use of wood from protection forests promotes the protective performance of the forest and helps to maintain the volume of work of wood-processing companies in the region. This generates a sustainable value chain that creates added value for forest owners, the forestry, sawmill and timber industry.

KIVO pendant lamp in the Casa Vitalé, Chur

VERTICO Pendant lamps in the kitchen of the Casa Vitalé, Chur

Sustainable timber construction with individualised lighting solution

KIVO pendant lamp in the corridor in the Casa Vitalé, Chur

METRON with shade 80 wall lamp in the bedroom of the Casa Viez

VIOR Ceiling lamp creates atmospheric entrance

CUBO Wall lamp in the staircase

Sustainable timber construction with individualised lighting solution

KIVO pendant lamp in the Casa Viez

Sustainable timber construction with individualised lighting solution

Sustainable timber construction with individualised lighting solution

Sustainable timber construction with individualised lighting solution

Sustainable timber construction with individualised lighting solution

PRODUCTS USED